Integrity.Collaborative.Purposeful.Innovative.

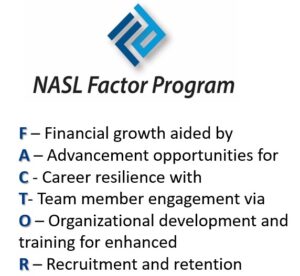

Team Member Value Proposition is at the Heart of our Efforts! We are committed to our internal staff for advancement opportunities, financial health, career resilience, engagement, and their wellness. With our people focused initiatives, we will drive to be the North American leader in differentiated lamination solutions to the building products industry.

We are determined to help you grow in our organization with custom training programs for our equipment to upskill your career.

Explore our website to learn more about what makes us – NASL!

North American Specialty Laminations (NASL) provides equal employment opportunities (EEO) to all employees and applicants for employment without regard to race, color, religion, sex, national origin, age, disability or genetics. In addition to federal law requirements, North American Specialty Laminations complies with applicable state and local laws governing nondiscrimination in employment in every location in which the company has facilities. This policy applies to all terms and conditions of employment, including recruiting, hiring, placement, promotion, termination, layoff, recall, transfer, leaves of absence, compensation and training.

You can apply using download a fillable PDF and email. This allows you to save your work and return to it at your convenience.

Download a job application form and e-mail to:

hr@northamercianlam.com

Or, mail your application to:

Human Resources

51149 Whitetail Road

Osseo, WI 54758